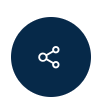

C135 Conveyor System

The robust C135 conveyor allows the user to continuously cut and convey single- to low-ply rolled material goods with consistent accuracy, speed, and control.

Product Summary

The Eastman Eagle C135 conveyor system boasts supreme capabilities for single- to low-ply cutting requirements. It has the ability to continuously convey rolled material goods with consistent speed and control. Eastman’s gantry and tool head design are engineered to cut the most diverse technical and industrial fabrics available, while exceeding industry standards for accuracy.

The robust conveyor design delivers unrivaled levels of material utilization and is often capable of cutting multiple layers without plastic overlay. This computer-controlled cutting system requires minimal operator guidance to automatically feed and spread material to the identified start position. The C135 offers tremendous efficiency when cutting pattern pieces that exceed the table length. The exclusive InMotion™ software enables the machine to continuously cut while conveying.

Available in a range of widths, lengths and various tool head accessory options, the C135 will be built to match your application needs, allowing you to customize the tools and capabilities to maximize productivity.

Automated > Automated Cutting

Features

Standard Features

- Choice of standard, heavy-duty or fiber tool head, featuring individually aligned and calibrated tool spindles with your choice of over 60 blades, punches and notches.

- A library feature within the operating control software allows the operator to save commonly used tool pressures and blade assignments based on job and material files.

- Prevent unauthorized changes to the system and software with restricted login access.

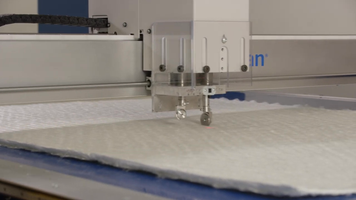

Cutting Surface

The cutting surface is a smooth and durable, high-durometer cast urethane conveyor belt suitable for even sticky or downy materials. It has proven reliable for 2,000+ hours of normal operation, with some customers testifying to more than four years of continuous use.

Material Hold-Down

The C135 is equipped with a self-contained, high-flow vacuum system to ensure optimum material hold-down for cutting. Millions of holes are perforated in a random pattern that provides evenly dispersed vacuum flow, no matter where you are cutting. The piece removal zone is integrated into the design, eliminating the need for extension tabling.

International Compliance Ratings

The operating computer, and control cabinet are housed in independent enclosures that are sealed to offer dust and water resistant protection in harsh or high particulate environments. Additionally, cabling connectors, servo motors and display components meet recognized international protection ratings requirements.

Industrial Design

- Advanced electro-pneumatic regulator for precise tool pressure control

- Heavy-duty cable connectors

- Hi/Low voltage systematic panel layout for easy troubleshooting

- Easy access, sealed doors for inspection and maintenance

- Heavy-gauge steel construction with scratch-resistant powder coated finish

- The series of drives is capable of Condition Based Predictive Maintenance. This is the practice of detecting changes in machine vibration and friction of your belt drives, linear guides, and gears so that parts can be replaced accordingly before they fail. This function automatically generates a failure warning limit so machine operators can schedule a service call to prevent machine downtime.

Download Product PDF

"*" indicates required fields

Additional Information

| Width | 78 in. (1.98 m) 96 in. (2.44 m) 108 in. (2.74 m) 114 in. (2.90 m) 126 in. (3.20 m) 156 in. (3.96 m) Please contact the factory for active cutting zone dimensions. Custom widths available, please contact the factory for more information. |

|---|---|

| Length | 16 ft. (4.88m) 20 ft. (6.10m) 36 ft. (10.97m) Please contact the factory for active cutting zone dimensions. Custom lengths available, please contact the factory for more information. |

| Drive System | Dual-X Axis, Y-Axis & Theta Axis. X & Y-Axis Rack & Pinion Drive, Brushless Servo Motors |

| Electric - Control Power/PC | 230V, 3 ph, 50/60 Hz, 5.4 kVA. Stand-alone step-down transformer required for other voltages. |

| Electric - Vacuum Blower | 208/230/380/460V, 3 ph, 50/60 Hz, 10 HP, VFD control |

| Power: Pneumatic | 75 – 90 psi at 15 SCFM (5.17 – 6.2 bars at 0.42 cmm) |

| Maximum Cutting Speed | 60 inches/second (152.4cm/second) |

| Maximum Conveyor Speed | 11 inches/second (28cm/second) System size dependent. |

| Maximum Acceleration | 1.3g |

| Maximum X/Y Speed | 60 inches/second |

| Compressed Air Consumption | 15 cfm |

| Sound Level | <76 db(A) |

| Operating Temperature | 55 – 100°F (12 – 37°C) |

| Humidity | 20 – 80% (non-condensing) |

Request a Quote

Get an individualized product quote from one of our application specialists. We’re here to help you configure a personalized cutting solution for your business.