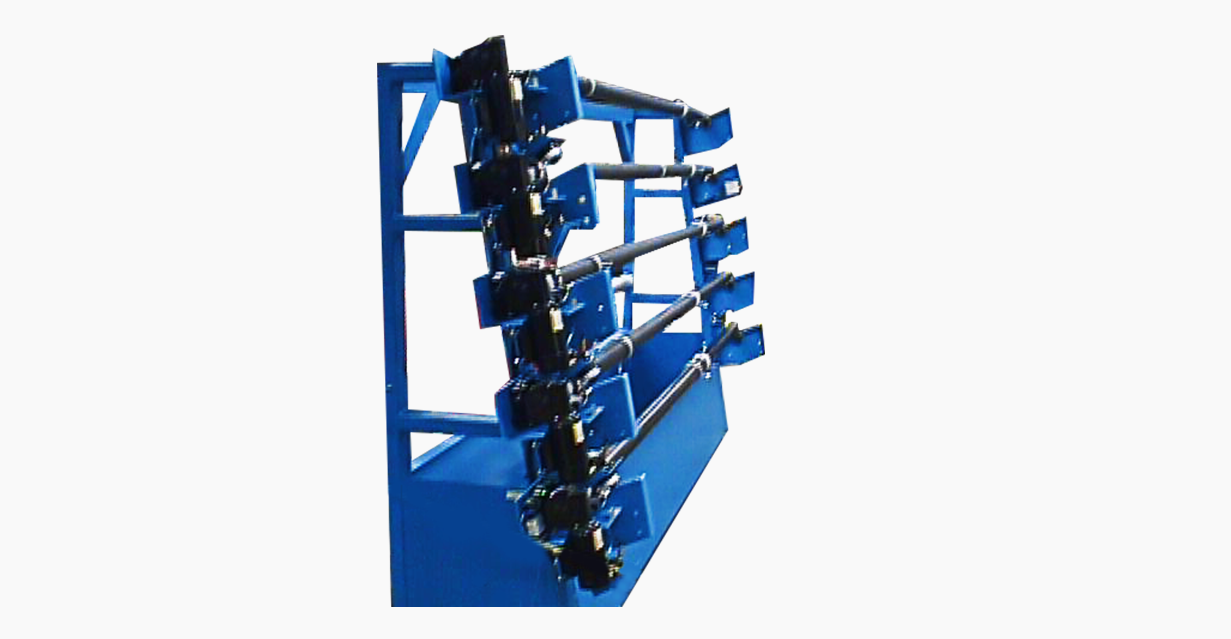

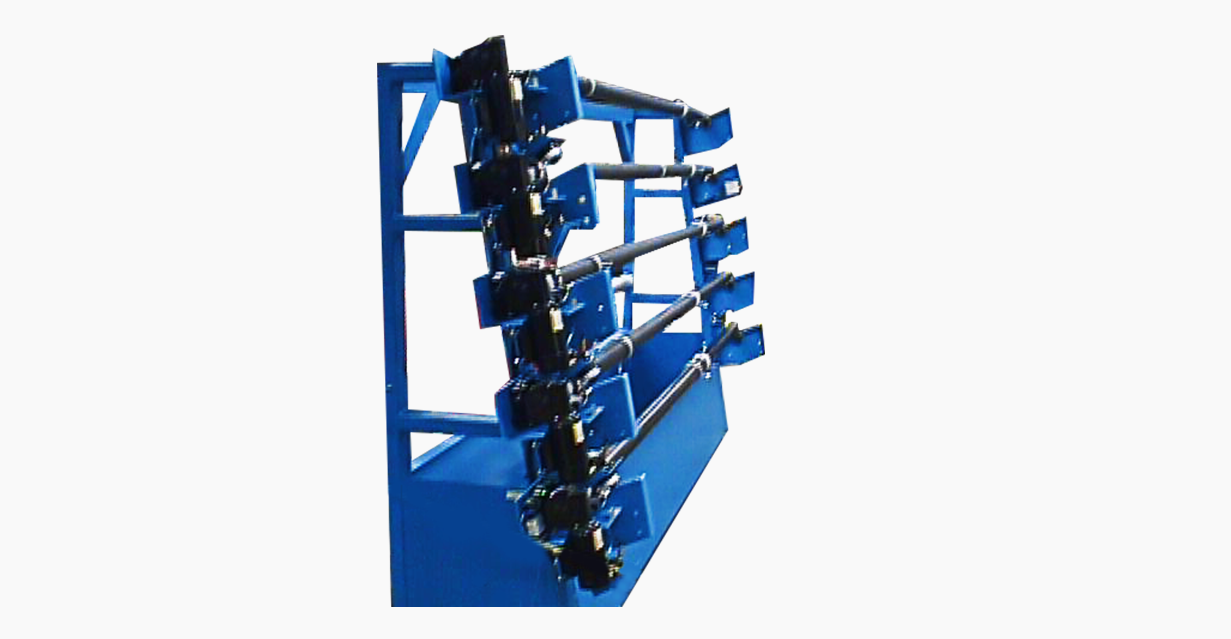

Rewinder, Floor Mount

Eastman’s series of material rewinders manage long-cut pieces with ease and streamline material handling operations after cutting. Available in floor or table mount configuration.

Product Summary

Eastman Material Rewinder works in synchronization with the conveyor cutting system as a means of managing long or cumbersome cut pieces. As cut pieces approach the node the operator pauses cutting to initiate rewinding on the core. Waste material continues moving along the system and drops into a collection bin.

The floor-mounted Material Rewinder is stationary at the take-off end of the conveyor and ideal for companies looking to minimize equipment footprint.

Material Handling > Material Rewinders

Features

- Located at the take-off end of the conveyor system

- Available in single or multiple node configurations

- Pneumatic clutch control

- Holds up to 100lbs (45.4kg) per bar

- Quick change core shafts

- Optional reverse winding

Download Product PDF

"*" indicates required fields

Additional Information

| Width | up to 180 inches (34.57m) |

|---|---|

| Maximum Rewind Speed | 11 inches / second (28 cm / second) |

| Horsepower | 1/4hp |

| Power Requirements | 110V, 1ph, 3 amps (per node); 220V, 1ph, 2 amps (per node) |

| Maximum Diameter (per node) | 12 inches (30.5cm) |

| Maximum Weight (per node) | 100 lbs (45.4 kg) |

Request a Quote

Get an individualized product quote from one of our application specialists. We’re here to help you configure a personalized cutting solution for your business.