Need a cutting surface you can rely on?

Eastman is here to help.

Indicate Machine Type

Cutting surface options vary, depending on your machine type: static or conveyor. Only two of the five cutting surface options have the ability to be seamed together for a conveyor cutting table.

Identify Application

There is no one-size-fits-all option when it comes to cutting surfaces. An Eastman specialist will assist in determining what cutting surface is best for your needs based on your application.

Request Quotation

Personalized support has been the standard at Eastman for over 135 years. After reviewing your cutting requirements, an Eastman specialist will provide a detailed proposal.

Single-ply Cutting Surface Options

The cutting surface configuration best suited to your cutting requirement and application will be recommended by an experienced Eastman representative. Looking for a replacement belt? All cutting surfaces can be tailored to equip any automated cutting machine.

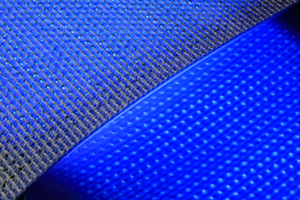

Blue Urethane (PU): cast 85 durometer, laser perforated

- Most popular surface

- Easy to clean, self-healing

- Comes in two thicknesses

- Cast 95 durometer available

- It has proven reliable for up to 2,000+ hours of normal operation, with some customers testifying to more than four years of continuous use.

Porous Plastic: semi-smooth, heat treated polypropylene (PP)

- Easily combine with other surfaces

- Strong hold down, hole diameter: 100-300 microns

- Most affordable surface, requires most maintenance

Lexan – clear, hard plastic, drilled holes

- Pair with porous plastic surface or mesh interlayer

- Slick surface for easy material spread

- Hard surface lays extremely flat

Clear/White Urethane (PU) – extruded 92 durometer, laser perforated

- Easily see contaminants on surface

- Harder surface, slightly less healing qualities

- Can be paired with porous plastic surface

Felt – thin, durable felt

- [Special Application] Designed to be used with oscillating or ultrasonic tool

- Easily flip or rotate to extend cutting surface life

- Use with porous plastic for multiple applications

Urethane Cutting Surfaces: Laser Perforation & Pattern

Hole perforation: The urethane cutting surfaces are individually perforated with a Class 4 laser. Hole diameters are strategically chosen depending on customer application and material type. The cone shape holes allow easy fall-out of unwanted debris while maintaining balanced air flow needed for cutting.

- STANDARD HOLE DIAMETER: 0.026 inches

Hole Pattern & Spacing: Depending on cutting surface size and material hold down requirements, the cutting surface patten and spacing of holes will vary. Hundreds of thousands of holes are perforated in an organized pattern on the belt, providing evenly dispersed vacuum flow.

NOTES: Some surfaces may require adhesive and seam sealing. Reperforation available upon request. Custom hole diameter, pattern, and spacing available upon request. For metric conversions, please contact factory.

Conveyor Cutting Surface Seam Options

Skive seam: diagonal tapered cut, belt ends are glued together

- Additional seam kit required for installation

- Technical installation, may need an Eastman technician

- Glue takes around 12 hours to cure, downtime of one day

Zipper seam: metal zipper added to belt ends, joined mechanically

- No glue or kit needed, minimum downtime around two hours

- Installation requires welding rod over seam

- Allows for easy removal and re-installation of belt

What to Expect When You’re Expecting a Cutting Surface

Order

Place order through Eastman rep.

Cut & Perforate

Surface is cut to size and perforated, if needed.

Crate

Order is prepared for shipping. Subject to crating fee.

Ship

Shipped via freight or other option chosen.

Deliver & Install

Surface is delivered and ready for installation.

FAQs

What surfaces are available for my machine?

- Static Table Compatibility: Porous Plastic, Felt, Lexan, Blue Urethane, Clear/White Urethane

- Conveyor Compatibility: Blue Urethane, Clear/White Urethane

What type of seam will my conveyor belt have?

- Zipper – This new seaming option eliminates the need for glue and excessive downtime while it dries. More importantly, the zipper seam is very easy way to install and/or remove the belt without the need for experienced technicians. The seam is just as it sounds- a series of metal loops intertwine, and a coated wire is inserted to hold everything together. A urethane welding rod is then melted with a heat gun on top of the seam to cover the metal zipper.

- Skive seam – The skive seam is a very technical installation as the belt is cut to size, perfectly aligned, and glued together. An additional seam kit is required for a skive seam installation.

Do the hole sizes vary with each material?

Yes. We have the ability to change the hole size, spacing, and pattern on the Lexan, Blue Urethane, and Clear/White Urethane surfaces. We suggest speaking with a representative before changing.

How long will my cutting surface last?

Cutting surface lifetime is dependent on many variables. A good way to ensure a longer cutting surface life is using the right amount of blade exposure for your material. If you have questions or are unsure, contact Eastman tech service before cutting.

Can you provide belts for machines not manufactured by Eastman?

Yes. Eastman will work with your group to provide a high-quality, reliable, replacement cutting surface for any automated cutting machine worldwide.

Request Form

Please fill out the form below and we will find the right replacement cutting surface for your application.