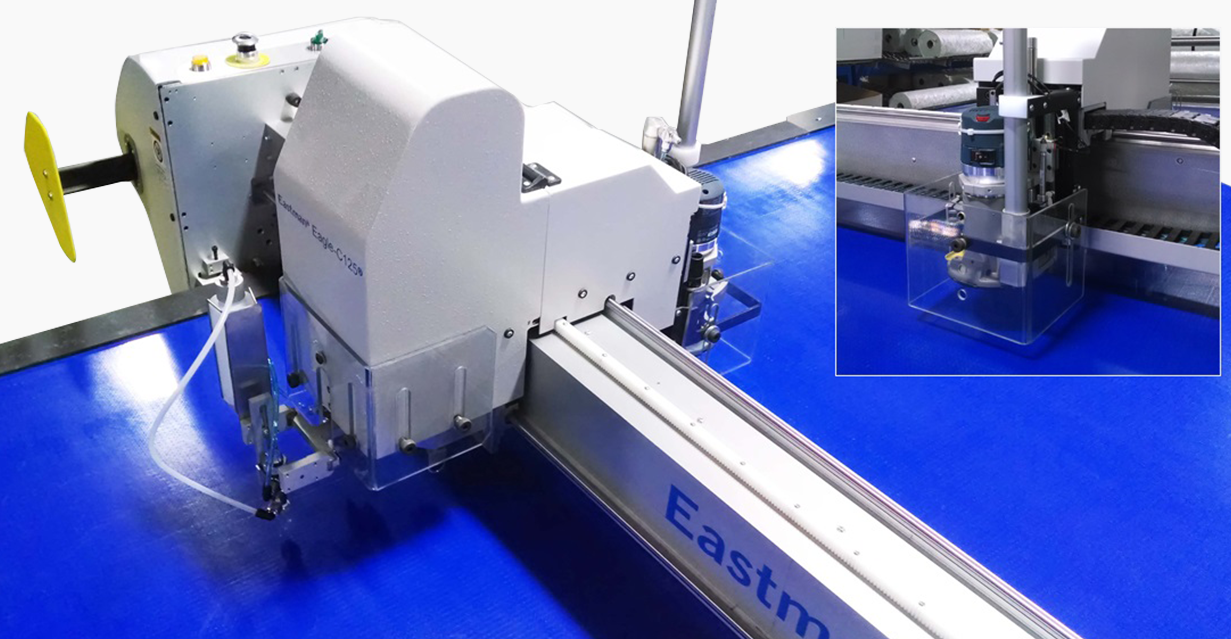

Combi Router - Cutting System

Eastman’s router tool head option offers a two-spindle tool head in addition to the router for a variety of cutting and routing options. It features a pneumatically controlled z-axis and a manually adjustable depth-control function.

Product Summary

Eastman’s router tool head option delivers heavy-duty performance for thick and dense materials. This system offers a two-spindle tool head in addition to the router for a variety of cutting and routing options. Features such as a pneumatically controlled z-axis and a manually adjustable depth-control function facilitate cutting materials such as soft or hard wood, composites, fiberboard, and a variety of plastics. A large-capacity debris-collection system helps create a clean work environment.

Available in a range of widths, lengths and various tool head accessory options, the S125 with laser will be built to match your application needs, allowing you to customize the tools and capabilities to maximize productivity.

Automated > Automated Cutting

Features

Standard Features

- Single- or low-ply layer cutting.

- Two spindle tool holders and a router.

- Exclusive carbon impregnated anti-static fiber belt for long life and cutting quality

- Sacrificial routing surface

- Large capacity router debris collection system.

- Available add-on for the conveyor or static table cutting systems

Cutting Surface

The standard surface for cutting with the router is a sacrificial routing surface. Standard cutting surfaces when operating with traditional blades.

International Compliance Ratings

The operating computer and control cabinet are housed in an ergonomic enclosure that can be sealed to offer dust and water resistant protection in harsh or high particulate environments. Additionally, cabling connectors, servo motors and display components meet recognized international protection ratings requirements.

Industrial Design

- Advanced electro-pneumatic regulator for precise tool pressure control

- Heavy-duty cable connectors

- Easy access, sealed doors for inspection and maintenance

- Heavy-gauge steel construction with scratch-resistant powder coated finish

Safety

- Gantry-mounted, laser enabled indicator light

- Four remote emergency stops: two on cutting gantry, two system-mounted

- Additional gantry-mounted stop disks pause system operation until returned to neutral and reset. Operation can then be resumed from any position

- Tool head is equipped with plexiglass safety window to keep hands free of knife during operation

- Single turn-off point with a universal power system for lockout/tagout safeguards employees from unexpected start-up

Additional Information

| Width | 60 in. (1.54m) 72 in. (1.82m) 78 in. (1.98 m) 96 in. (2.44 m) 108 in. (2.74 m) 114 in. (2.90 m) Please contact the factory for active cutting zone dimensions. Custom widths available, please contact the factory for more information. |

|---|---|

| Length | 8 ft. (2.44m) 12 ft. (3.66m) 16 ft. (4.88m) 20 ft. (6.10m) 36 ft. (10.97m)+ Please contact the factory for active cutting zone dimensions. |

| Drive System | Dual-X Axis, Y-Axis & Theta Axis. X & Y-Axis Rack & Pinion Drive, Brushless Servo Motors |

| Electric - Control Power/PC | 115/230V, 1 ph, 50/60 Hz, 3.6 kVA |

| Electric - Vacuum Blower | 208/230/380/460V, 3 ph, 50/60 Hz, 7.5 HP, VFD control optional |

| Power: Pneumatic | 75 – 90 psi at 15 SCFM (5.17 – 6.2 bars at 0.42cmm) |

| Maximum Cutting Speed | 60inches/second (152.4cm/second) |

| Maximum Acceleration | 0.5g |

| Compressed Air Consumption | 15 CFM |

| Sound Level | <75 db(A) |

| Operating Temperature | 55 – 100°F (12 – 37°C) |

| Humidity | 20 – 80% (non-condensing) |

Request a Quote

Get an individualized product quote from one of our application specialists. We’re here to help you configure a personalized cutting solution for your business.