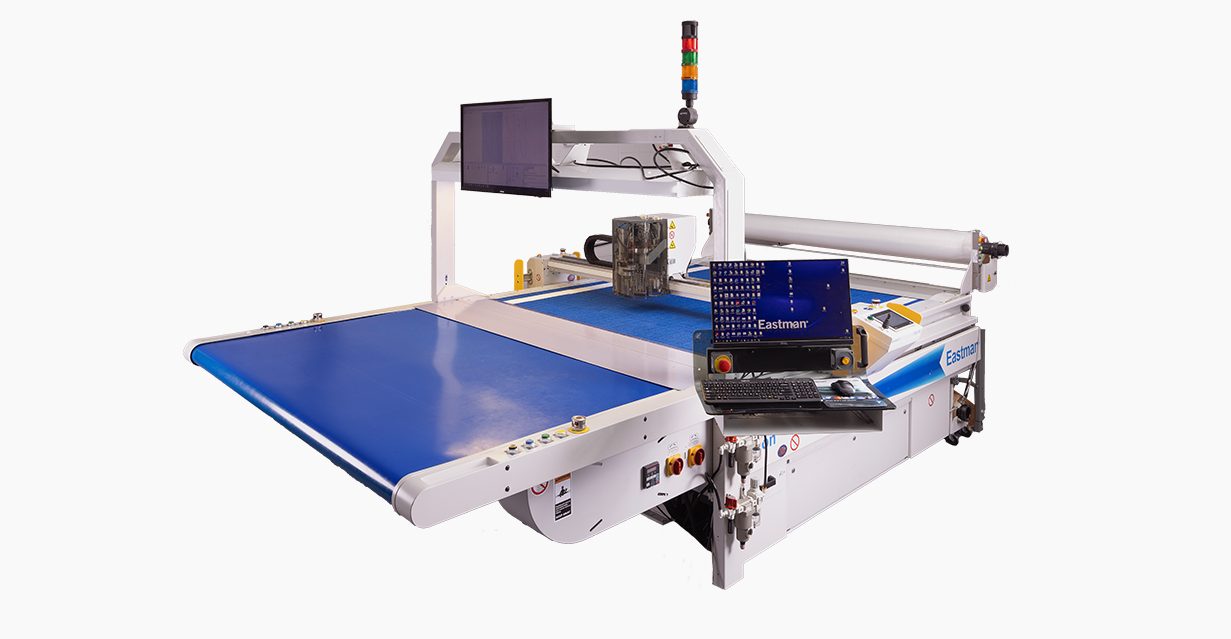

Talon Multi-Ply

The Talon offers an industrial-strength cutting solution for high-ply production facilities with capabilities to cut up to 3 in. (7 cm) of compressed material goods.

Product Summary

The Eastman Talon Multi-Ply is engineered and manufactured in the USA to automatically pull stacked material plies from the spreading table to a modular, bristle-block conveyor bed for reciprocating knife cutting of patterns. Precise system operations with state-of-the-art motion control communications offer an industrial-strength solution. The Talon 25 can cut up to 1.18 in. (3 cm) of compressed material goods, while the Talon 75 has the capabilities to cut up to 3 in. (7 cm) of compressed material goods.

The Talon has been engineered to meet the demands of clients in growing market segments like industrial fabrics and composites industries; customers cutting traditional -as well as- modern technical materials like kevlar, fiberglass, nonwoven polyesters, foam-backed vinyl and other industrial fabrics.

Automated > Automated Cutting

Features

Standard Features

- Materials database

- Power consumption reduced through intelligent vacuum controls

- Easy to replace, the bristle blocks used in cutting area

- Washable filters

- Internal silencer

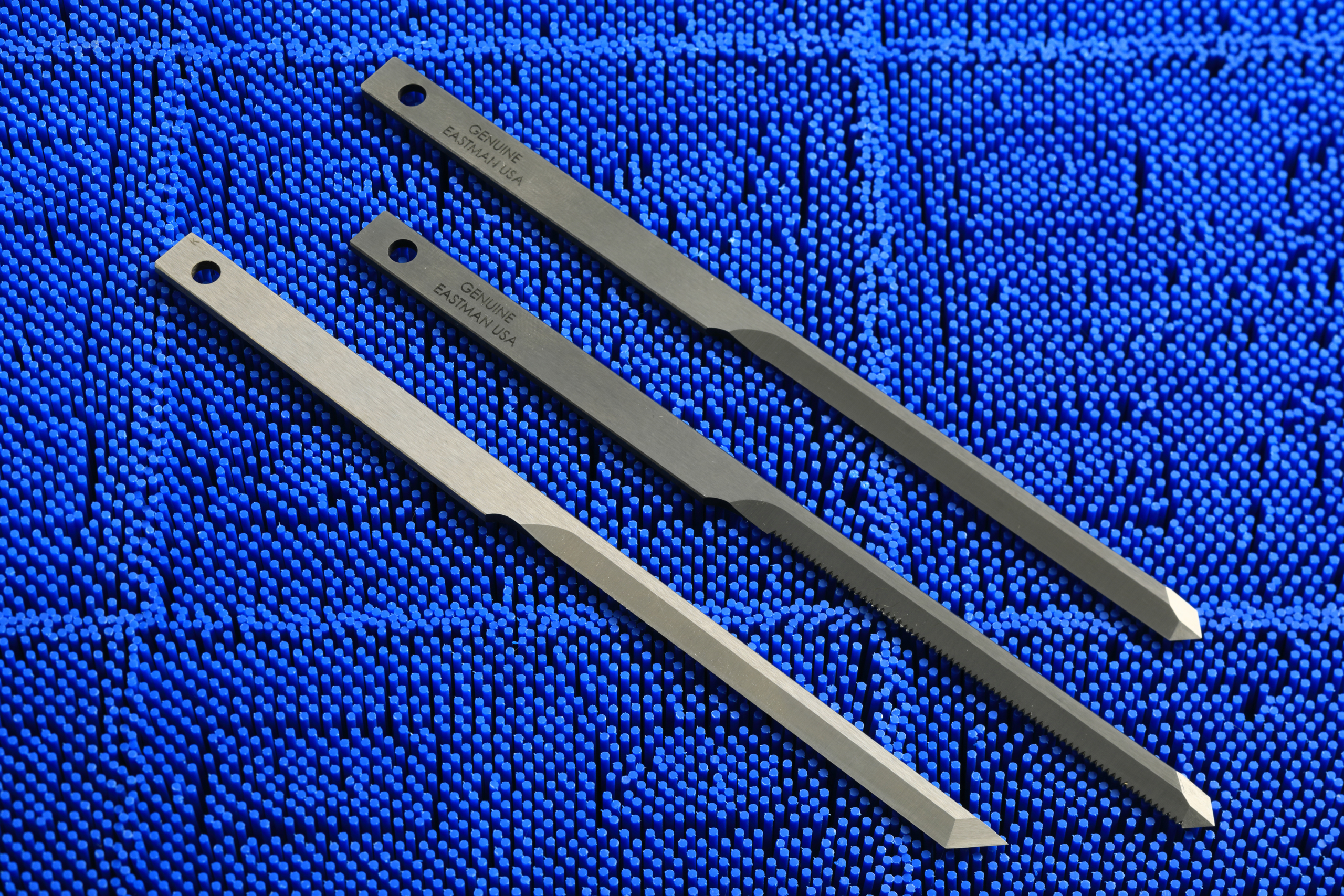

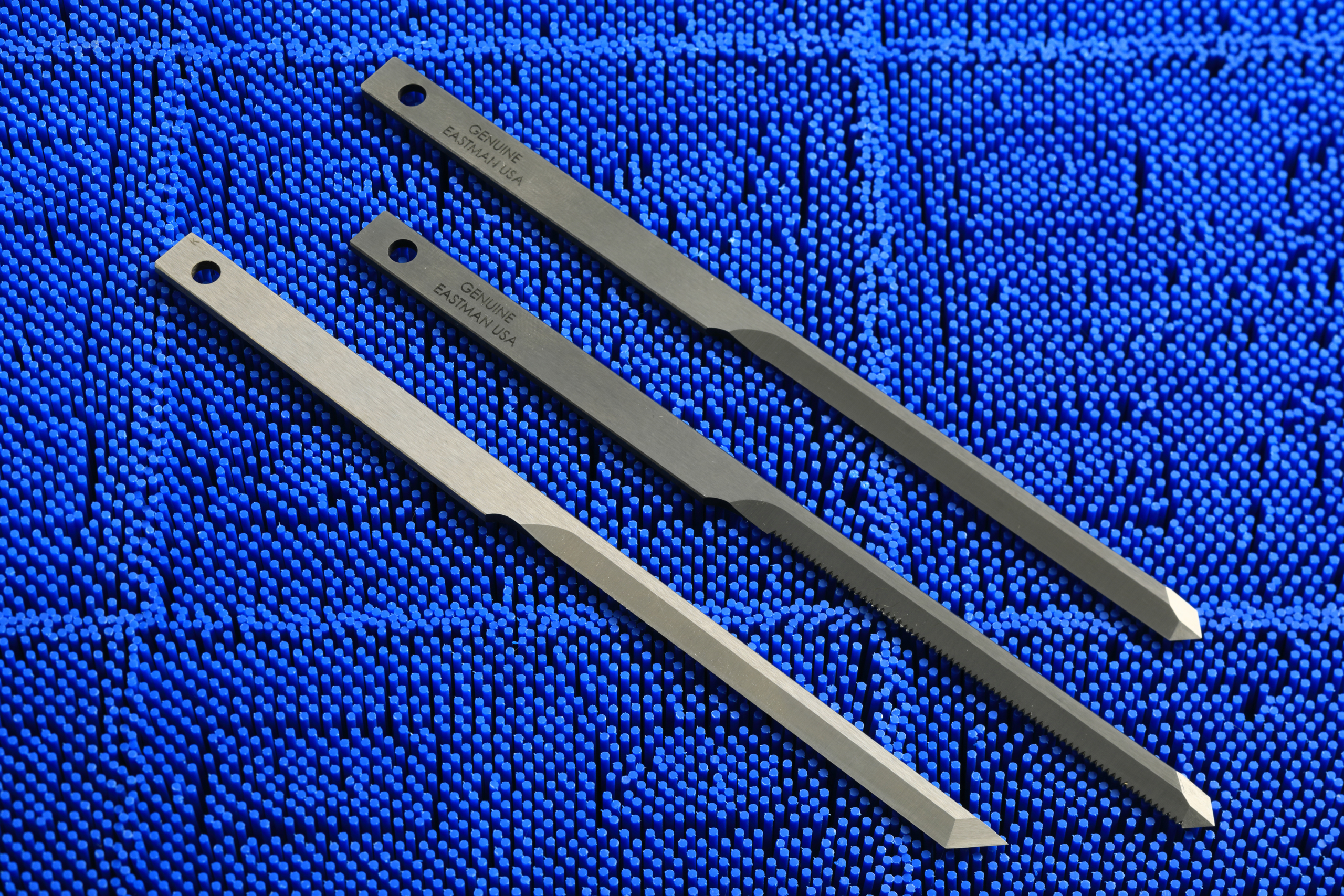

Tool Head

- The Talon Tool Head, patent pending

- Quick change knife and sharpening disc

- Reciprocating knife provides precise vertical stroke cutting

- Intellicut knife control software ensures high-quality, precise cuts from top to bottom ply (75x only)

- Talon 25: can cut up to 1.18 in. (3 cm) of compressed material goods

- Talon 75: can cut up to 3 in. (7 cm) of compressed material goods

- Single coated diamond disc provides the perfect cutting edge. Sharpener can be adjusted to user defined angle.

- High-speed-single or dual pneumatic drills

- Internal crank cooling system reduces heat and wear/tear

- Easy access to knife system and assembly parts simplifies daily maintenance procedures

- Direct drive knife system for fewer moving parts and less wear and tear

- Blade wear monitor

- Control of corners to minimize fusing

Safety

- Six remote emergency stops

- Additional gantry-mounted stop discs pause system operation until returned to neutral and reset. Operation can resume from any position.

- Tool head is equipped with a transparent safety cover

- Single turn-off point with a universal power system for lockout/tagout safeguards employees from unexpected start-up

- Stack light indicator marks operation status

Additional Information

| Cutting Area Width | Talon 25: 78 inches (2.0 m) |

|---|---|

| Overall Machine Width | 111 inches (2.84 m) |

| Cutting Area Length | 5.5 ft. (1.68 m) |

| Overall Machine Length | 13 ft. (3.96m); 4 ft. (1.22m) unloading conveyor |

| Drive System | Dual-X Axis, Y-Axis & Theta Axis. |

| Max. Thickness of Compressed Material | Talon 25: 1.18 in. (3 cm) |

| Electric - Control Power | 208/230/380/460/575V, 3 ph, 50/60 Hz, 9.0 kVA |

| Electric - Vacuum Blower | 208/230/380/460/575V, 50/60 Hz, 25 HP, VFD control |

| Pneumatic | 90 psi (6.2 bars), 18 cfm |

| Maximum Cutting Speed | Up to 40 in./sec (101.6 cm/second) – material dependent |

| Maximum Conveyor Speed | 8 in./sec. (20.3cm/min) |

| Maximum Acceleration | 1.0 g |

| Sound Level | <76 dB(A) |

| Operating Temperature | 55 – 100°F (12 – 37°C) |

| Humidity | 20-80% (non-condensing) |

Request a Quote

Get an individualized product quote from one of our application specialists. We’re here to help you configure a personalized cutting solution for your business.